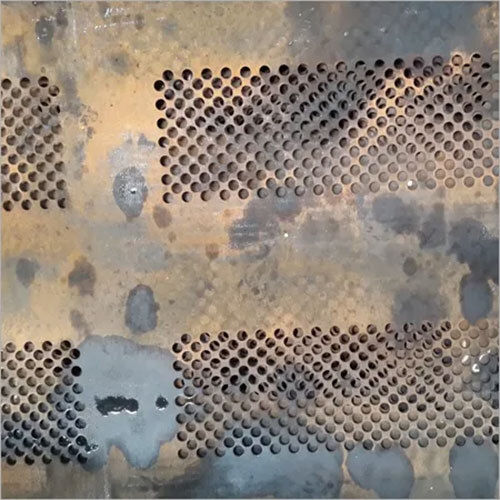

Perforated Plate

Price 86.0 INR/ Square Foot

Perforated Plate Specification

- Surface Treatment

- Plating

- Usage

- Industrial

- Material

- Stainless Steel, Metal, Steel, Aluminum Alloy, Galvanized Sheet

- Type

- Perforated Plate

- Size

- Standard

- Technique

- Perforated

- Product Type

- Perforated Plate

- Color

- Grey

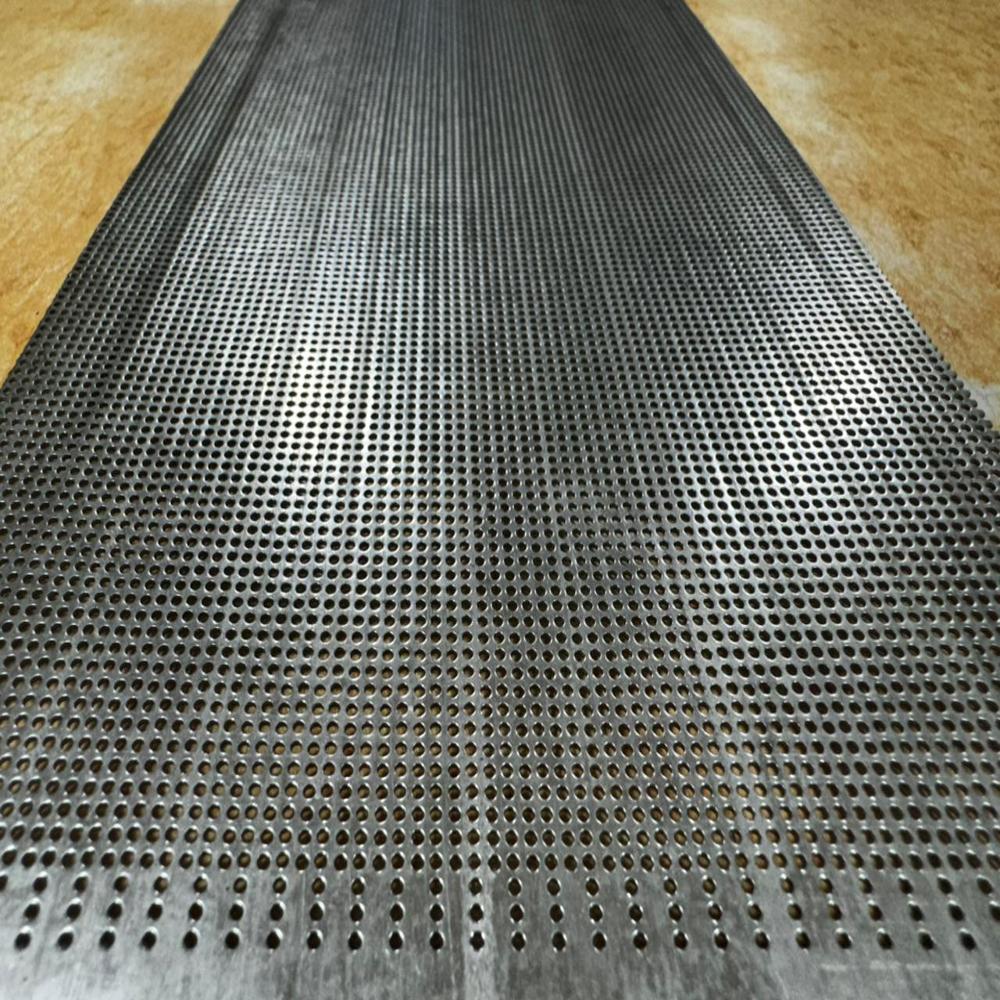

- Width

- 4 Foot (ft)

- Length

- 8 Foot (ft)

- Application

- Exhaust system components, grilles, and engine covers for heat and noise management.

Perforated Plate Trade Information

- Minimum Order Quantity

- 100 Square Foots, Square Foot

- Payment Terms

- Cash Advance (CA)

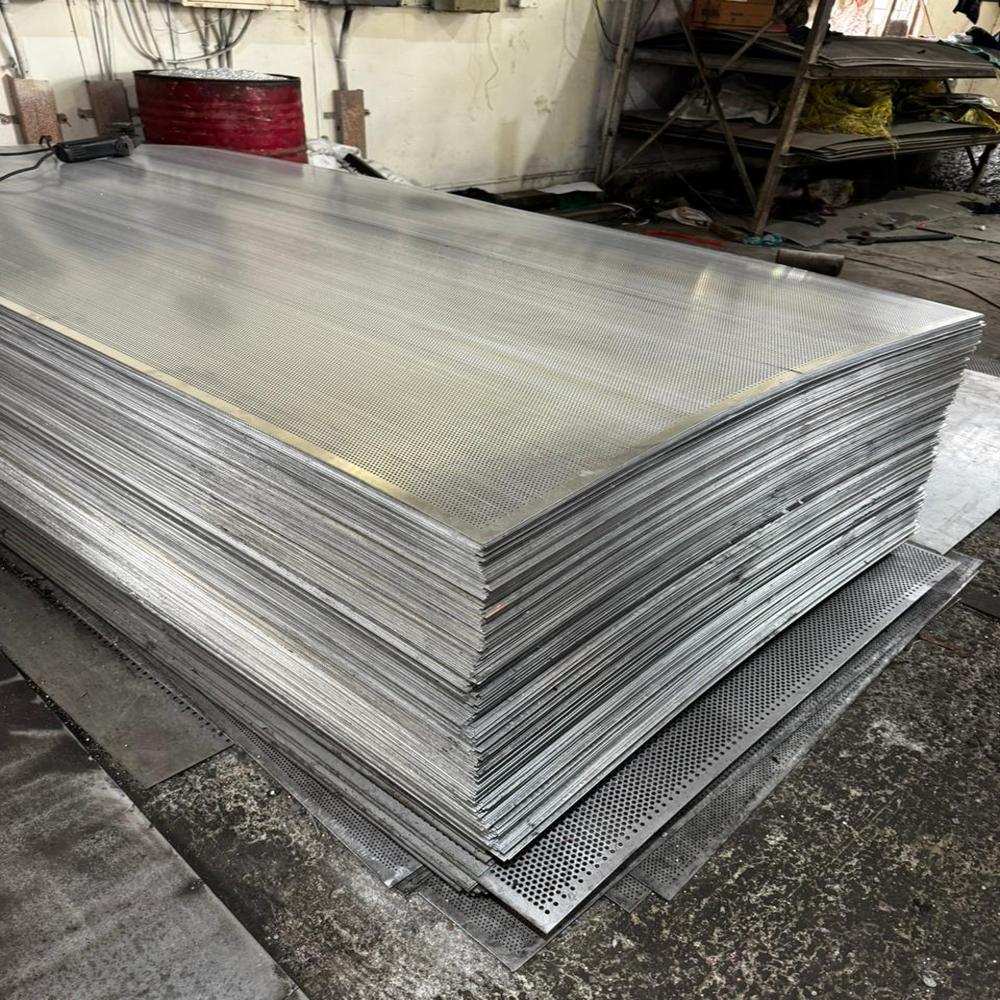

- Supply Ability

- 5000 Square Foots, Square Foot Per Month

- Delivery Time

- 4 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Perforated Plate

Having both quality and client centric approach, we have been engaged in manufacturing, exporting and supplying broad array of Perforated Plate. The offered plate is manufactured using top notch quality raw materials and pioneering techniques as per set industry norms. To fencing the wall, the provided plate is used for keeping away dust and restricted the entry of birds. Moreover, our valuable patrons can easily avail this Perforated Plate at rock bottom rates from us.

Features:

- Sturdy design

- Easy to install

- Long lasting life

- Perfect finish

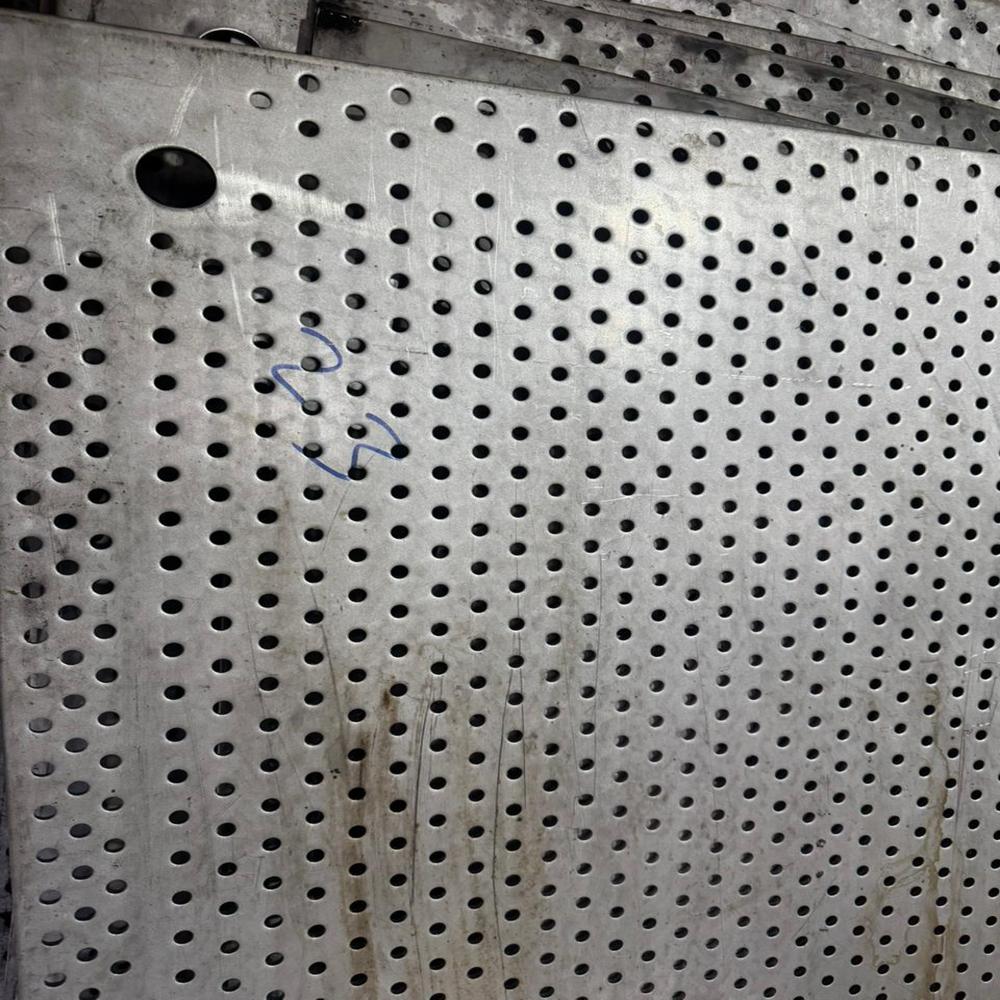

Engineered for Industrial Performance

Our steel perforated plates offer exceptional strength and durability, meeting stringent industrial standards. Their versatile nature allows deployment in filtration, screening, and protective barriers across multiple industries, ensuring reliable performance even in demanding environments.

Superior Surface Protection

Each plate is treated with high-quality plating, providing superior resistance to corrosion and wear. This ensures longevity and minimizes maintenance requirements, making our perforated plates a valuable investment for extensive industrial usage.

Trusted by Businesses Nationwide

As a leading manufacturer, distributor, exporter, and wholesaler, we cater to clients throughout India. Our commitment to quality and timely delivery has earned us the trust of industry professionals seeking dependable perforated steel solutions.

FAQs of Perforated Plate:

Q: How is the perforated plate manufactured?

A: Our perforated plates are produced using advanced perforation techniques on high-quality steel sheets. The process ensures uniform hole sizes, precise patterns, and smooth edges, followed by plating to enhance surface protection.Q: What are the main industrial applications of this perforated plate?

A: These steel perforated plates are widely used in filtration, ventilation, screening, acoustic panels, safety guards, and machine enclosures. Their versatility makes them suitable for multiple industrial sectors.Q: When should I choose a plated perforated plate over an untreated one?

A: Plated perforated plates are ideal when you require enhanced corrosion resistance or additional surface protection, especially in environments exposed to moisture, chemicals, or varying temperatures.Q: Where can these perforated plates be installed?

A: They can be fitted in factories, processing units, construction sites, protective enclosures, and other industrial settings where strength, ventilation, or filtration is required.Q: What is involved in the surface plating process?

A: After perforating the steel sheet, the plates undergo a plating process that deposits a protective metal coating on the surface, which enhances durability and resistance to environmental factors.Q: How does the plating benefit the performance of the plate?

A: Plating significantly extends the service life of the plate by protecting it from rust, corrosion, and surface abrasions, ensuring consistent performance in demanding industrial conditions.Q: What sizes are available, and can custom dimensions be provided?

A: Our standard sizes cater to most industrial needs. However, for specific applications, we can offer custom dimensions upon request, depending on your projects requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Perforated Sheets Category

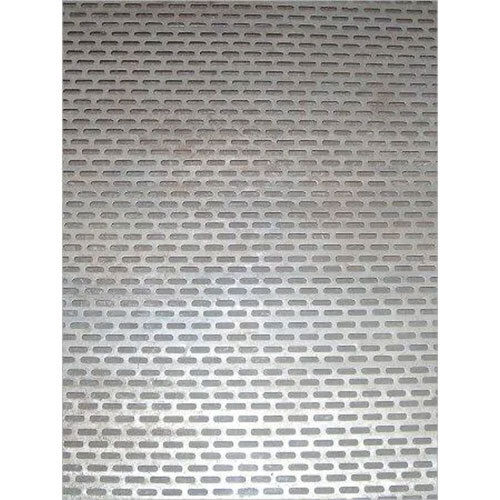

Slot Hole Perforated Sheet

Price 200.0 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Product Type : Slot Hole Perforated Sheet

Usage : Industrial

Material : Steel

Size : Standard

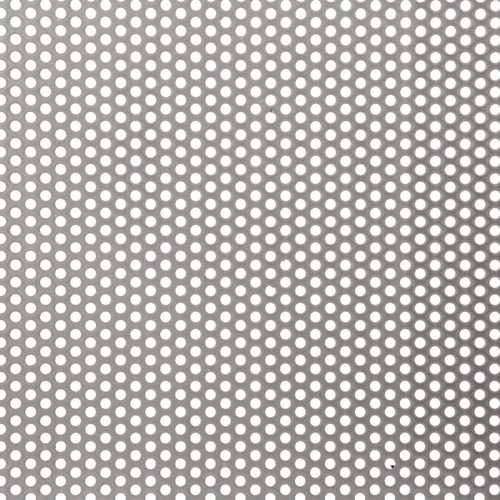

Perforated Metal Sheets

Price 75.0 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Product Type : Perforated Metal Sheets

Usage : Industrial

Material : Metal

Size : Standard

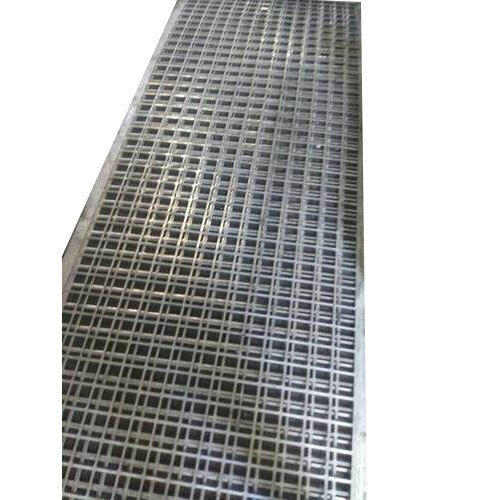

Mild Steel Perforated Sheets

Price 3000 INR

Minimum Order Quantity : 10 Pieces

Product Type : Mild Steel Perforated Sheets

Usage : Industrial

Material : Other

Size : Standard

Perforated Composite Sheet

Price 100 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Product Type : Perforated Composite Sheet

Usage : Industrial

Material : Steel

Size : Standard

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese