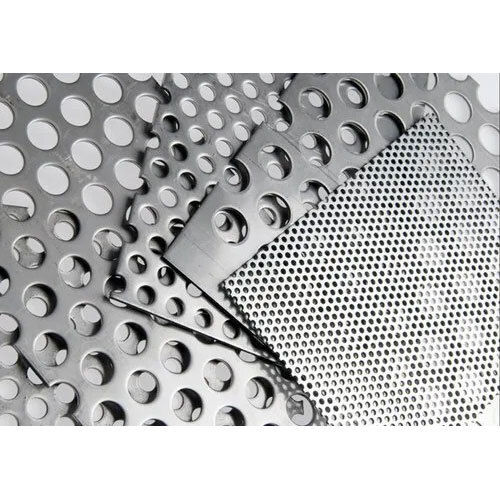

Perforated Composite Sheet

Price 100 INR/ Square Foot

Perforated Composite Sheet Specification

- Surface Treatment

- Plating

- Usage

- Industrial

- Material

- Steel

- Size

- Standard

- Type

- Perforated Composite Sheet

- Technique

- Perforated

- Product Type

- Perforated Composite Sheet

Perforated Composite Sheet Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 100 Square Foots Per Week

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Perforated Composite Sheet

Having huge industrial expertise in this domain, we have emerged as a leading manufacturer, exporter and supplier of the best quality array of Perforated Composite Sheet. Under the observation of deft professionals, the offered sheet is manufactured at our premises using quality examined raw materials and innovative techniques. The provided sheet is ideal to be used in applications of all kinds, both indoor and outdoor. Besides, this Perforated Composite Sheet is easily available in markets to our esteemed patrons at economical rates from us.

Features:

- High strength

- Smooth surface

- Rugged design

- Extended durability

Precision-Engineered for Industrial Excellence

Our Perforated Composite Sheets are manufactured using state-of-the-art perforation techniques, ensuring uniform hole patterns and robust structural integrity. The steel material is carefully plated for enhanced durability, corrosion resistance, and prolonged service life. These sheets offer reliable solutions across various sectors, including construction, automotive, and chemical industries, where performance and longevity are paramount.

Versatile Applications and Easy Customization

Designed for versatility, our composite sheets support multiple industrial uses such as enclosures, safety guards, and decorative panels. Their standard sizing and adaptable nature allow seamless integration into existing systems, while custom options are available upon request. The plated finish not only protects the steel but also gives a clean, professional appearance suitable for visible installations.

FAQs of Perforated Composite Sheet:

Q: How is the perforated composite sheet manufactured?

A: These sheets are made from steel that undergoes precision perforation, where holes are mechanically punched in a uniform pattern. Subsequently, the sheets are plated to provide a corrosion-resistant surface, ensuring durability for industrial use.Q: What are the main industrial applications of perforated composite sheets?

A: Perforated composite sheets are widely used in industries for applications such as screening, ventilation, filtration, protective guards, partitions, and architectural cladding due to their strength and versatility.Q: When should I choose a plated perforated composite sheet over a non-plated one?

A: A plated sheet is ideal for environments exposed to moisture, chemicals, or weathering, as the plating adds an extra layer of protection against corrosion and wear, extending the sheets lifespan.Q: Where can your perforated composite sheets be supplied?

A: We serve customers across India and also cater to export markets globally, providing reliable supply to various industries through our channels as a distributor, exporter, manufacturer, and wholesaler.Q: What benefits does the perforated design offer for industrial usage?

A: The perforated design enhances airflow, allows for drainage, reduces material weight, and enables filtration, all while maintaining structural integritymaking these sheets adaptable for numerous complex applications.Q: How can the sheets be integrated into existing industrial systems?

A: Available in standard sizes, the sheets can be easily fitted or further cut and shaped as needed. Their consistent pattern and dimensions ensure compatibility with various assembly processes and fixtures.Q: What is the process for placing a bulk order or requesting customization?

A: You can contact us directly through our sales or support channels to discuss your requirements. We offer bulk order solutions with options for custom perforation patterns, sizes, and surface treatments to match your specific needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Perforated Sheets Category

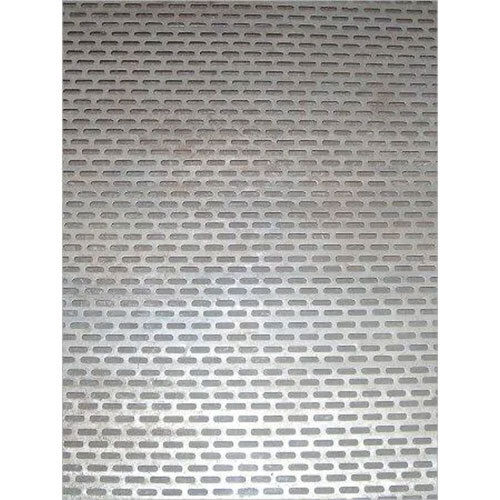

Slot Hole Perforated Sheet

Price 200.0 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Usage : Industrial

Product Type : Slot Hole Perforated Sheet

Material : Steel

Size : Standard

Square Hole Perforated Sheet

Price 55 INR / Square Foot

Minimum Order Quantity : 2000 Square Foots

Usage : Industrial

Product Type : Square Hole Perforated Sheet

Material : Steel

Size : Standard

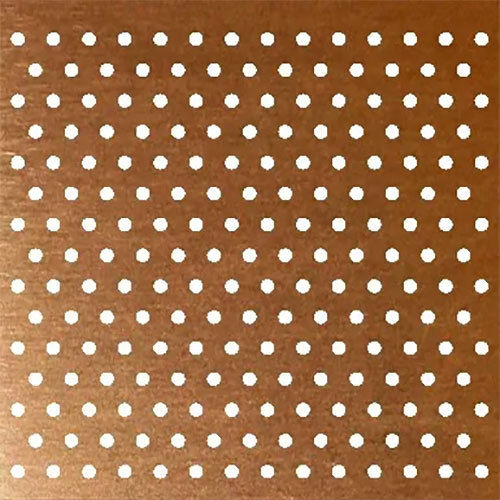

Copper Perforated Sheet

Price 600 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Usage : Industrial

Product Type : Copper Perforated Sheet

Material : Other

Size : Standard

Titanium Perforated Sheet

Price 35000 INR / Piece

Minimum Order Quantity : 1 Kilograms

Usage : Industrial

Product Type : Titanium Perforated Sheet

Material : Other

Size : Standard

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese